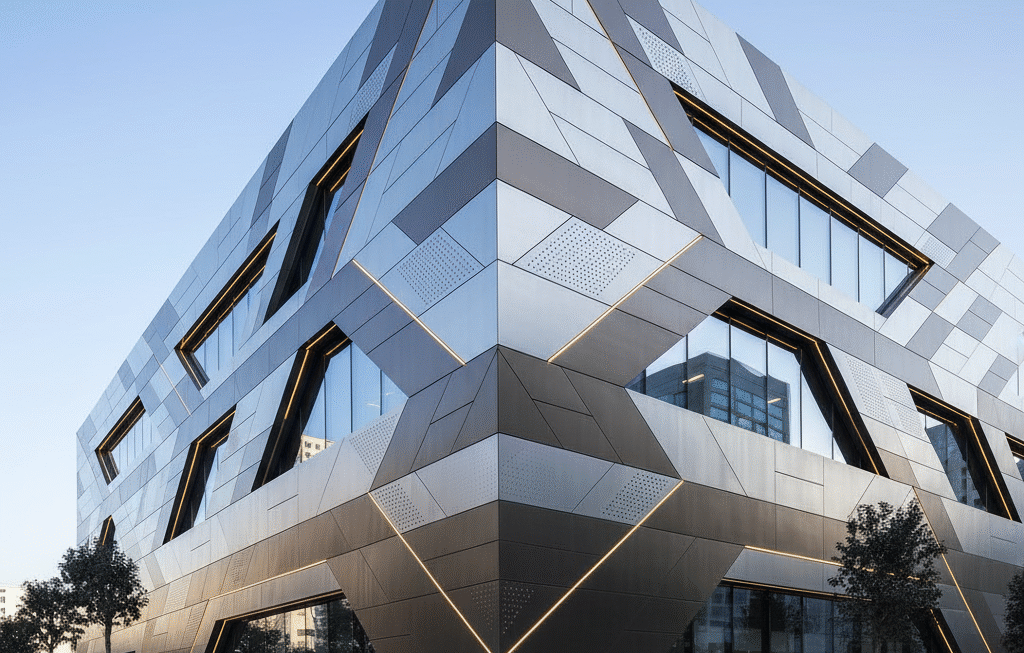

Aluminum cladding facade offer a durable, lightweight, and versatile solution for modern building exteriors. They provide excellent protection against weather while allowing for a wide range of design options, including various colors and finishes. Their combination of strength, energy efficiency, and recyclability makes aluminum cladding a practical choice for commercial and residential projects alike.

These panels are prized for their ability to withstand harsh environmental conditions without compromising aesthetic appeal. They also support sustainable construction practices due to their recyclable nature and less intensive production impact compared to other metal cladding materials.

Beyond durability, aluminum cladding systems often feature advanced attachment technologies that ensure easy installation and maintenance. This adaptability makes aluminum a preferred material in contemporary architecture for enhancing both functionality and style.

Overview of Aluminum Cladding Facade

Aluminum cladding facades combine strength, lightweight construction, and design flexibility. They offer protection against environmental elements and enhance the visual appeal of buildings. Their various types cater to different structural and architectural needs, with distinct benefits related to durability and energy efficiency.

What Is Aluminum Cladding Facade?

An aluminum cladding facade is an exterior covering system using aluminum panels to protect and decorate a building’s surface. These panels are precision-engineered, typically incorporating interlocking designs and supported by subframes and insulation layers. This structure enhances thermal insulation and weather resistance while maintaining a lightweight form.

The system shields buildings from moisture, wind, and fire without adding excessive weight. It also supports modern architectural styles by allowing smooth, clean finishes and customizable panel shapes and colors. Aluminum’s corrosion resistance and recyclability make it a practical choice for sustainable construction.

Types of Aluminum Facade Systems

There are three primary types of aluminum facade systems: composite panels, solid panels, and aluminum siding.

- Composite panels consist of two aluminum sheets bonded to a core material, offering flexibility in design and enhanced energy efficiency.

- Solid panels are single aluminum sheets known for strength and long-lasting durability, ideal for heavy-duty applications.

- Aluminum siding is a cost-effective option, commonly used in residential buildings for straightforward installation and weather protection.

Each type serves specific building requirements based on aesthetics, budget, and performance factors. Choosing the right type depends on the project’s demands for strength, insulation, and design freedom.

Key Features and Benefits

Aluminum cladding facades are valued for being lightweight yet highly durable. Their resistance to corrosion and weather damage reduces maintenance needs over time. Panels typically come pre-coated, eliminating the need for painting or polishing.

Energy efficiency is a significant benefit; aluminum facades can integrate insulation to lower heating and cooling costs. The rainscreen design allows water to drain effectively, protecting the building envelope from moisture-related issues. Additionally, aluminum facades are fire-resistant and contribute to a building’s structural integrity while providing modern aesthetic appeal.

Applications and Installation Methods

Aluminum cladding facades are widely used across various building types due to their durability, aesthetics, and functional benefits. The installation methods focus on ensuring longevity, weather resistance, and ease of maintenance. Customization plays a significant role in meeting specific architectural requirements.

Common Uses in Modern Architecture

Aluminum cladding is common in commercial, residential, and industrial buildings. Its lightweight nature and corrosion resistance make it suitable for high-rise structures and exterior walls exposed to harsh weather.

Public buildings often use aluminum composite panels to create sleek, modern exteriors. Residential projects benefit from its energy efficiency and design flexibility. Industrial facilities utilize solid or perforated aluminum panels to improve ventilation and durability.

Due to versatility, aluminum cladding fits various architectural styles, from minimalist façades to complex geometries. It also supports sustainable building efforts by facilitating insulation and reducing energy consumption.

Installation Techniques

Installation typically involves securing panels using methods that balance strength and ventilation. The rainscreen system is popular, creating an air gap between the aluminum cladding and the wall for moisture control and insulation.

Fastening methods include mechanical fixing with screws or rivets and adhesive bonding, depending on panel type and substrate. Proper site preparation, including leveling and weatherproofing, is crucial before installation.

Installers often follow a step-by-step process: panel layout planning, frame installation, panel fixing, and sealing joints for water resistance. Hiring experienced professionals ensures compliance with safety standards and project specifications.

Design and Customization Options

Aluminum cladding offers various finishes, including anodized, powder-coated, and painted surfaces, allowing customization for color and texture. This flexibility supports aesthetic goals while enhancing durability.

Panel types vary from solid sheets to perforated and honeycomb structures, offering options for ventilation, light diffusion, and weight reduction. Sizes and thicknesses can be tailored to suit structural and design needs.

Designers can integrate features like embedded lighting, curved panels, and integrated signage, expanding the material’s architectural potential. These options enable precise adaptation to project requirements without sacrificing performance.